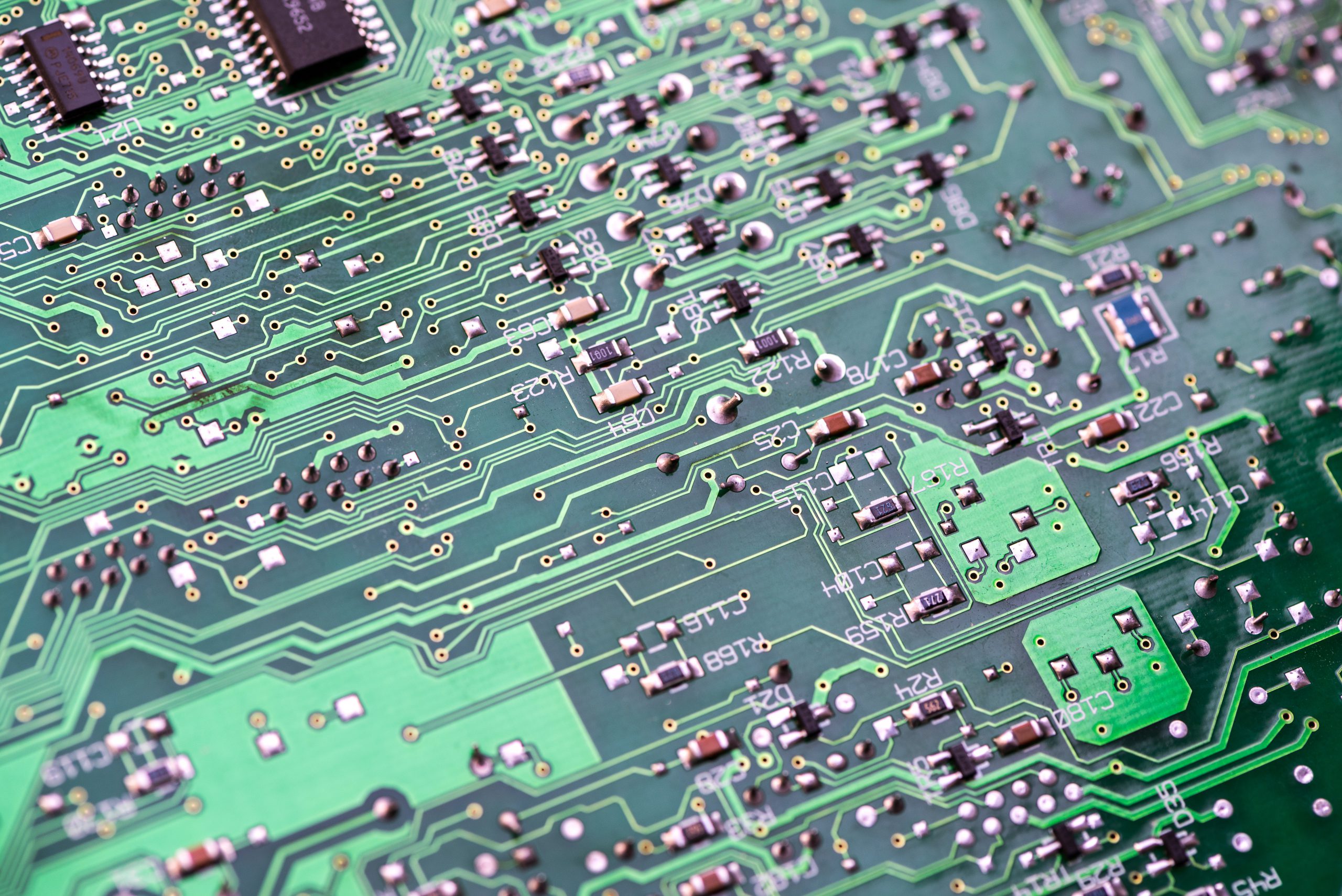

Hole-In-The-Wall PCB Impedance management determines the resistance of such traces & ensuring that they are within the design’s limitations when the PCB is manufactured. Despite its high cost, this method became popular around the turn of the century because of the ever-increasing frequencies of electrical components. Know all about circuit board maker.

A printed circuit board’s copper-plated holes, known as Vias, connect the layers. Surface Mount Technology’s standard is a through-hole via, although this has several drawbacks (SMT). Instead, we employ a blind via or buried via when building circuit boards for this purpose. A blind and buried via mask can be treated in various ways, such as with a plugged copper mask via, a plugged solder mask via, a plated via, or a phased via, among others.

Multilayer PCBs can be used in various applications, including consumer electronics, medical devices, aerospace, telecommunications, military vehicles, automobiles, wearables, and the Internet of Things (IoT). As a Singapore-based PCB board manufacturer, Promax Technology Integration has been working hard to provide high-quality multilayer PCBs with complete specifications and reduced lead times for consumers.

Research and development of turn-key solutions and products

“Turnkey” refers to any product or service ready to use when it is delivered to the customer. Regarding custom PCB assembly solutions, Promax Technology Integration manages all aspects of the process, from component sourcing and PCB production to selecting and installing components on the PCBs at specific sites. A turnkey PCB implementation means that the purchasing company can focus solely on PCB design while we handle the rest.

A few PCB manufacturing businesses in Singapore will work with you to create and plan all of the elements above for your business. R&D may also be utilized to enhance a current product or service, resulting in entirely developing a new product or service line.